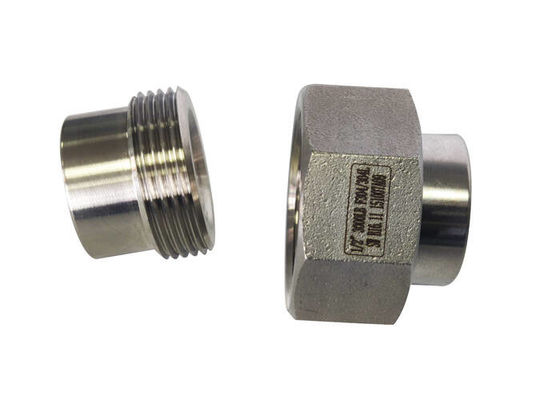

Butt welded union 140KG high pressure pipe fittings 2000LB spherical hard seal

Name Title: Stainless steel high-pressure socket union

Specification: DN6, DN8, DN10, DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100. The commonly used order specifications are DN15 ---- DN50. If it exceeds the scope of this specification, it can communicate with customers to design and process drawings.

Compression force: 3000LB, 6000LB, 9000LB or SCH80, SCH160, XXS

Material quality: carbon steel (CS), stainless steel (SS), alloy steel (AS)

Standards: GB / T14383-93, GB / T14383-2008, American Standard ASME B16.11, Petrochemical Standard SH3410, Ministry of Chemical Industry Standard HG / T21634, etc.

The stainless steel socket union is to connect the steel pipe and the union joint first, and then use the movable advantage of the union to automatically adjust the connection seal. It does not need to be welded when it is connected with the steel pipe, which is beneficial to fire prevention, explosion-proof and aerial work, and can eliminate the disadvantages caused by careless welding.

Products range:

| Products Name |

Socket Union |

| Material |

SS304 /316L stainless steel |

| delivery time |

15 days for sample; 30-days for production |

| Color |

Silver |

| Design |

OEM & ODM |

| MOQ |

50 pcs |

| Free Sample |

Yes |

| Packaging details |

Wooden boxes, Boxes, Plastic bags |

| Port |

shanghai china |

Precautions:

The stainless steel union joint consists of a male port, a female port, and a sleeve female. The male port has a spigot at one end to match the female mouth of the female port; the other end has an inner wire, which is connected to the outer wire of the stainless steel tube as a short wire. The inner hole of the sleeve mother has an inner wire, and the inner wire is connected with the outer wire on the mother mouth. The sleeve female is set at one end of the male port, and the inner wire of the sleeve female is directed to the female port. Before the sleeve is locked, the male and female ports must be aligned correctly, and the contact surface is flat, otherwise it is easy to leak. When replacing the union, it should generally be replaced by a full set. Otherwise, due to the inconsistency of the product, the male and female ports are not tightly coordinated, which is likely to cause leakage.

Inspection and Test Procedure

| 1.100% PMI,Spectro Chemical Aanlysis Test for Raw Material |

| 2.100% Dimension & Visual Examination |

| 3. Mechanical Properties Test Include Tension Test,Flaring Test (For Seamless tube/pipe)/ Flange Test (For Welded Pipe & Tube), Hardness Test ,Reversed Flattening Test |

| 4.100% Hydrostatic Test or 100% NON-DESTRUCTIVE Test (ET or UT) |

| 5.Radiographic Test for Welded Pipe (shall be accordance with specification,or shall be as agreed upon between the purchaser and vendor) |

| 6.Straightness Test (optional) |

| 7.Roughness Test (optional) |

| 8.Intergranular Corrosion Test(optional) |

| 9.Impact Test (optional) |

| 10.Grain Size Determinations (optional) |

| NOTES : ALL THE TESTS AND INSPECTION RESULT NEED TO BE SHOWED IN REPORTS ACCORDING TO STANDARD AND SPECIFICATION. |

About US

The company's production from the beginning of the acquisition of raw materials, spectrometer material before the furnace test, precision processing and surface treatment, after the most stringent quality control, to meet the requirements of the guests. The accessories can pass the world-class food hygiene and ety standards. We produce a variety of different specifications such as SMS, IDF, 3A, DIN, DS, RJT / BSM. Demands for various situations. You are welcome to call or e-mail to consult with business staff at any time!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!