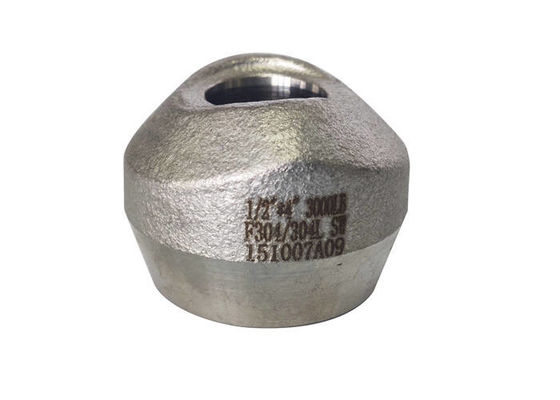

Butt-welding branch weldolet olets high pressure pipe fittings 3000LB forged saddle reinforced

"zheheng steel"Fast delivery weldolets insert weldolet weldolet sockolet threadolet definicion weldolet sockolet

Prodution range:

Product name :Outlets /weldolet

Size :1/2"- 24" seamless, 4"-48" seam welding

Wall thickness :2MM----25MM

SCH5,SCH10S, SCH10, SCH20, SCH30, STD, SCH40,

XS, SCH60, SCH80, SCH100, SCH120, SCH140,

SCH160, XXS, SGP, LG,

Certification :ISO9001: 2008, PED.

Standard :ANSIB16.9, ASME B16.28; DIN 2605, DIN 2615, DIN2616,

DIN2617;GOST 17375; GOST 17378; JIS2311

Application :

Chemical industry, petroleum industry,

construction industry, power industry,

gas industry, shipbuilding ,domestic installation

Pressure :PN6,10,16,25,40,

Grade :

ASTM / ASME SA 182 F 304 , 304L , 304H, 309H, 310H ,

316 , 316H , 316L , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H

Technics :Forged

Material:Carbon steel ,stainless steel ,alloy steel

EN 10216-2 (P235GH,P265GH)

EN10222-2(P245GH,P280GH)

NF A49-213 (TU42C,TU48C)

Low Alloy Steel : ASTM A-420(WPL6)

ASTM A-234(WP11,WP22,WP5)

ASTM A-860(A860-WPHY52)

Stainless Steel: ASTMA403M (WP304,WP304L,WP304H,WP316,WP316L,WP321,

WP321H,WP347,WP347H) EN10216-5(X2CrNiN18-10(1.4311),

X5CrNi18-10(1.4301),X5CrNiMo17-12-2(1.4401),X2CrNiMo17-12-2(1.4404)

Type:Outlets /weldolet

what is the weldolets ?

Butt welded weldolet is a kind of olets that has been widely used in foreign countries in recent years. It is a reinforced pipe fitting used for branch pipe connection. Reliable, reduced cost, simple construction, improved medium flow channel, series standardization, convenient design selection and other outstanding advantages, especially in high pressure, high temperature, large diameter, thick-walled pipes are increasingly used, replacing the traditional branch pipe connection method.

The main body of the olets is made of high-quality forgings, and the materials are the same as those of the pipeline, including carbon steel, alloy steel, stainless steel, etc. Both the olets and the main pipe are welded. The olets and the weldolet or other pipes (such as short pipes, wire plugs, etc.), instruments, valves are connected with butt welding, socket welding, thread and other types. Standard: MSS SP 97, GB / T 19326, pressure: 3000 #, 6000 #

why choose us:

| 1.100% PMI,Spectro Chemical Aanlysis Test for Raw Material |

| 2.100% Dimension & Visual Examination |

| 3. Mechanical Properties Test Include Tension Test,Flaring Test (For Seamless tube/pipe)/ Flange Test (For Welded Pipe & Tube), Hardness Test ,Reversed Flattening Test |

| 4.100% Hydrostatic Test or 100% NON-DESTRUCTIVE Test (ET or UT) |

| 5.Radiographic Test for Welded Pipe (shall be accordance with specification,or shall be as agreed upon between the purchaser and vendor) |

| 6.Straightness Test (optional) |

| 7.Roughness Test (optional) |

| 8.Intergranular Corrosion Test(optional) |

| 9.Impact Test (optional) |

| 10.Grain Size Determinations (optional) |

| NOTES : ALL THE TESTS AND INSPECTION RESULT NEED TO BE SHOWED IN REPORTS ACCORDING TO STANDARD AND SPECIFICATION. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!